Cleaving Sapphire Tools

Sapphire Cleaving Applications

Cleaving is a simple and fast technique used to prepare samples of silicon and other semiconductor materials, but sapphire, even though it is a single crystal, does not cleave well. Current methods for downsizing sapphire involve sawing and cleaving but yields are unsatisfactory due to fractures in unwanted directions and loss of material during the process. Laser scribing and cryogenic cooling are mentioned in literature as methods that can reduce unwanted fractures, delamination, chipping and loss of material but these methods are costly, time consuming and can present other undesired issues like edge quality and thermal damage due to temperature changes.

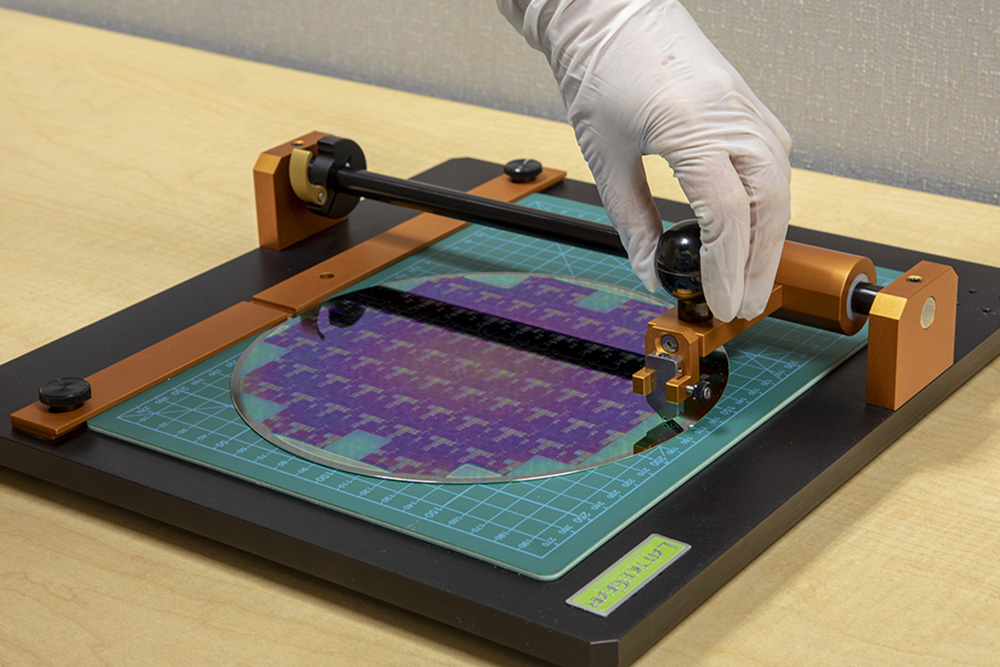

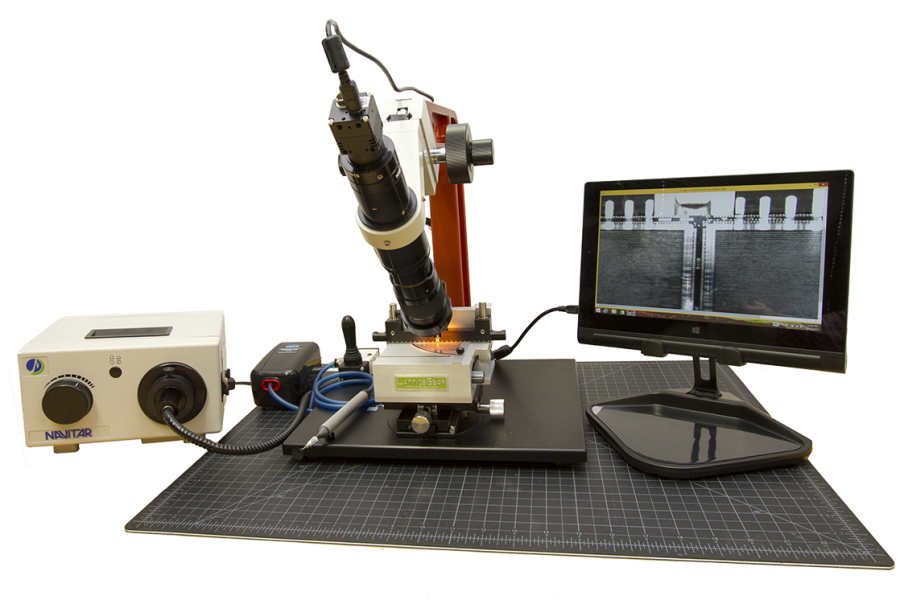

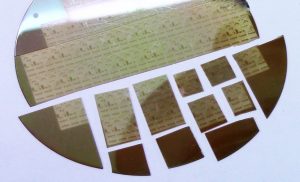

As cleaving is fast, low cost with no loss of material, several 3” sapphire wafers were acquired by LatticeGear to revisit cleaving of sapphire using two recently developed methods. These methods are differentiated from handheld scribing and cleaving because they integrate diamond indenting, scribing and cleaving into a mechanical platform. The “smart” mechanics (knobs, levers, dials) enable a repeatable process and remove variation in results based on the operator. It also allows for new test conditions that are not possible with handheld processes. READ MORE and WATCH VIDEOS

Cleaving explained

Step 1. Weak point creation

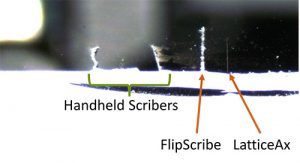

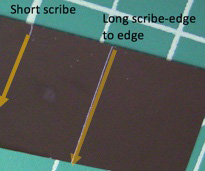

The weak point is a defect created on the sample. It will be the initiation point for the cleave. It is not possible to split a substrate into two pieces without first making a weak point using a diamond scriber or indenter. The weak point is made on the edge of the sample (Right) and is very important as it defines the accuracy and quality of the cleave because the cleave propagates from the weak point. If the weak point is made at an angle, is wide, or causes fractures both accuracy and quality of the cleaved surface will be negatively effected.If you need to cleave the sample counter to crystal planes or on amorphous materials you must make a long scribe. These materials will "want" to cleave on crystal planes or the path of least resistance.

Step 2. Cleaving

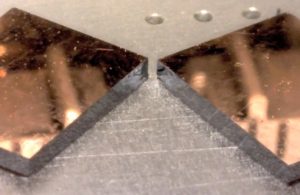

The second step in preparing a cleaved sample is cleaving. Cleaving occurs by creating stress on the weak point. The cleave is then initiated and propagates across the sample. If the sample is crystalline, the best weak point is short as it initiates a cleave following a crystal plane. The resulting cross section will have a mirror finish (Right). If the sample is amorphous, the sample will break but without a crystal plane, the cleave will propagate in the direction of the weak point but may not be straight unless a long scribe is made scribed across the entire desired line of cleavage. The resulting cross section will not have a mirror finish. This “long scribe” approach is also used on crystalline material when the line of cleavage needs to be counter to the crystal plane. The far right images shows a silicon sample cleaved at 45 degrees to the (100) crystal plane. Note that because the cleave is counter to the crystal plane the edge is rough. A three point cleave provides a good cleave and is achieved by creating pressure on the sample underneath the scribe and two pressure points on top of the sample, equidistance from the scribe. Three point cleaving can be done by splitting the sample in two with fingers, cleaving wire, pliers, Small Sample Cleaver or indenting and cleaving tool such as the LatticeAx.

Solutions

When cleaving sapphire, since it is hexagonal in crystal structure and very hard, it is very important to understand the orientation of your wafer prior to cleaving. In addition, you need to know whether crystal facets are required and/or downsizing along patterned structures is needed. The cleaving process flow and tools needed will be depend on the desired outcome. So ask yourself?Do I need mirror finish edges (typically needed for photonics devices)?

- Do I need mirror finish edges (typically needed for photonics devices)?

- What is my substrate size and thickness?

- Do I want to cleave samples for cross section analysis by SEM?

The solution may require one or more tools to get the job done. For instance:

- For downsizing large thin (<200 micron) wafers into 1 cm2 die, no mirror finish required. Use the FlexScribe with PCD diamond cutting wheel.

- To cleave thick 6" sapphire wafers you will need heavy duty 8" CleanBreak pliers

- For preparing samples that must have mirror finish facets for photonics or SEM analysis. Downsize with the FlexScribe or FlipScribe and make the final cleave with the LatticeAx.

- Preparing samples that have sensitive thin films on the surface. Use the FlipScribe backside scriber to downsize the samples. Make the final cleave using the LatticeAx to obtain mirror finish facets.

Don't see your application here, CONTACT US for a recommendation.

Products for Cleaving Sapphire

Sapphire can be difficult to downsize cleanly and safely. Based on your application LatticeGear can recommend the right tool set. Please contact us!

Important Accessories

There are a some accessories that will be important for your laboratory.

CleanBreak Pliers with 3 Sets of Jaws. After scribing you will need to cleave your sample. It is possible to cleave over a sharp edge but the pliers provide symmetrical force when cleaving sapphire. Cleanbreak pliers are used for samples 20mm/.75" and larger.

For thick 6" sapphire wafers, the FlexScribe and FlipScribe will be your go to tools. Cleave with heavy duty 8" Cleanbreak pliers, for more info ASK US.

Videos

Watch videos showing the operation of the scribing and cleaving tools and systems.

Publications

Publications (for copies, contact lg@latticegear.com) or for downloadable copies of these publications you must be registered and signed in