Learn About Cleaving With LatticeGear

Dicing a glass wafer

Glass wafers are used for a wide variety of applications, from semiconductor processing to microfluidic chips used for biotechnology devices. As a result, LatticeGear™ receives many questions about solutions to cleanly and quickly dice wafers without costly equipment.

In our previous post we introduced basic concepts to consider when cutting glass by scribing and cleaving. Concepts such as:

- Do I need to have mirror finish facets (the facet is the cut edge)?

- Do I need to have rectangular samples (orthogonal edges)

There are many ways to cut glass. Using scribing and breaking methods as we will show here are simple and clean. We don’t use lubricants but clean our cutting wheels and pointed scribers frequently. We don’t lose material as the cleaving process simply separates the pieces in comparison to a dicing saw. Another important benefit is that the scribe and break method does not generate a toxic waste stream that needs to be disposed.

It can be quite intimidating to cleave a large glass wafer. We have cleaved thick glass plates as large as 500 mm2 and wafers 300 mm in diameter and 500 microns thin. Borosilicate, fused silica and quartz glass are all best cleaved using diamond cutters and scribes. Soft soda lime glass typically, used for glass slides can be cut with tungsten carbide cutters as well as diamond scribes. Table 1 provides an overview of common glass types.

Dicing a wafer with the FlexScribe

To illustrate the glass cutting process, we will use a 4”(100mm) borosilicate wafer 500 microns thick using the FlexScribe topside scriber. See the video below. The process was as follows:

- Cleave in half

- Cleaving into quarters

- Make 1cm wide strips

- Cleave into 1cm2 chips

Table 1. A short overview of glass types

| Soda lime glass (most common), low resistance to thermal shock , can be tempered to strengthen and increase thermal shock resistance. ( 5-6 Moh’s) |

| Borosilicate glass, resistant to thermal shock (5.5 Mohs’ Scale, Knopp 470). Pyrex from Corning is synonymous for borosilicate glass. |

| Quartz glass. Low thermal expansion coefficient resistant to shock. (5.5-6.5 Mohs’ Scale). Made by fusing low grade synthetic or naturally occurring quartz. More impurities than fused silica. |

| Fused silica (5.5-6.5 Mohs’ Scale). High purity as it is made by fusing high purity synthetic material. Pure used for photonic applications. High transmission in the UV compared with quartz. |

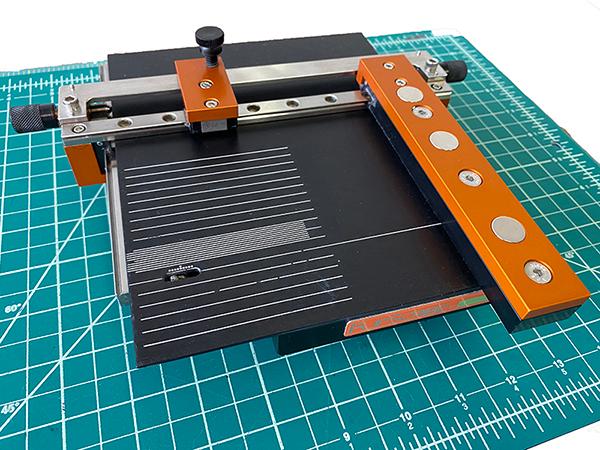

Using the FlipScribe to cleave small samples

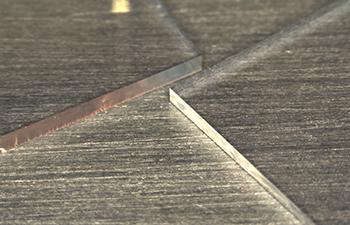

We have also downsized fused silica and quartz glass. Figure1a shows a fused silica wafer downsized using the FlipScribe, backside scribing tool. The FlipScribe has ruled markings and horizontal and vertical guides to use when scribing. This makes it easy to scribe multiple samples with high repeatability and accuracy. The FlipScribe small sample holder shown in Figure 2b made it easy to handle the chips when they were about an inch/25mm or less. Figure 1b shows the edge quality that is achieved scribing with the FlipScribe and cleaving using Cleanbreak pliers.

Figure 2a shows the FlipScribe used for scribing the backside of the glass wafer. Figure 2b shows a number of the tools used to handle and cleave the glass wafer chips shown in this post. These items are found in the Cleaving station available from LatticeGear.

Important Tips

Scoring/scribing glass

You will get the best cut by making a single scribe with gentle even pressure that produces a fine, visible line on the glass. You do not want to go so deep that fractures are observed.

Cleaving/breaking

When you split your pieces after scribing, the highest success and best facets will be obtained if you use the rule of halves. The rule of halves states that you cut is most likely to run straight when you have equal amount of glass on either side of the scribe. In short, avoid cutting a thin strip off of a large plate of glass.

Find more helpful information on our webpage on Cleaving Glass.

Don't see your application here, CONTACT US for a recommendation.

Product Recommendations

FlipScribe (up to 4” wafer)

FlexScribe (up to 300 mm wafer, standard borosilicate glass)

FlexScribe with diamond scriber (up to 300 mm wafer, quartz glass, thin glass)

The Cleaving Station with everything to need to scribe and cleave using handheld tools

Carbide cutter cleaving kit (general glass cutting)

Handheld scribers (general glass cutting)

Cleanbreak Pliers with 3 sets of jaws 6” handle (cleaving glass and crystalline substrates)

Cleanbreak Pliers with 3 sets of jaws 8” handle (cleaving thick glass and sapphire)