Nanomaterials and Nanofabrication

Cleaving Applications

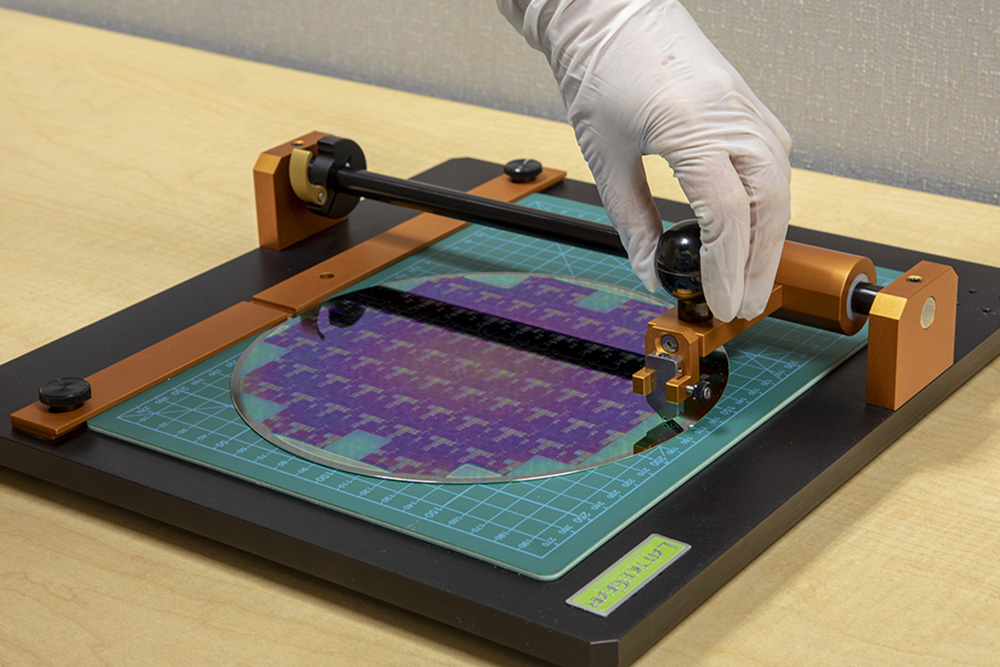

In the research environment, one typically does not use the full wafer when fabricating devices. Getting the most out of expensive wafers requires downsizing. Cleaving is a desired sample method because it is fast, dry and clean. Here we present examples where cleaving is used to downsize nanomaterials and nanofabricated devices. WATCH VIDEOS

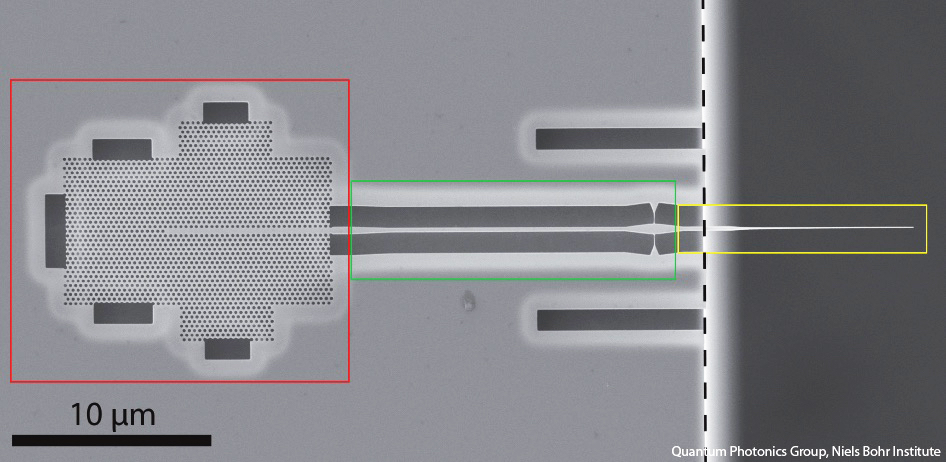

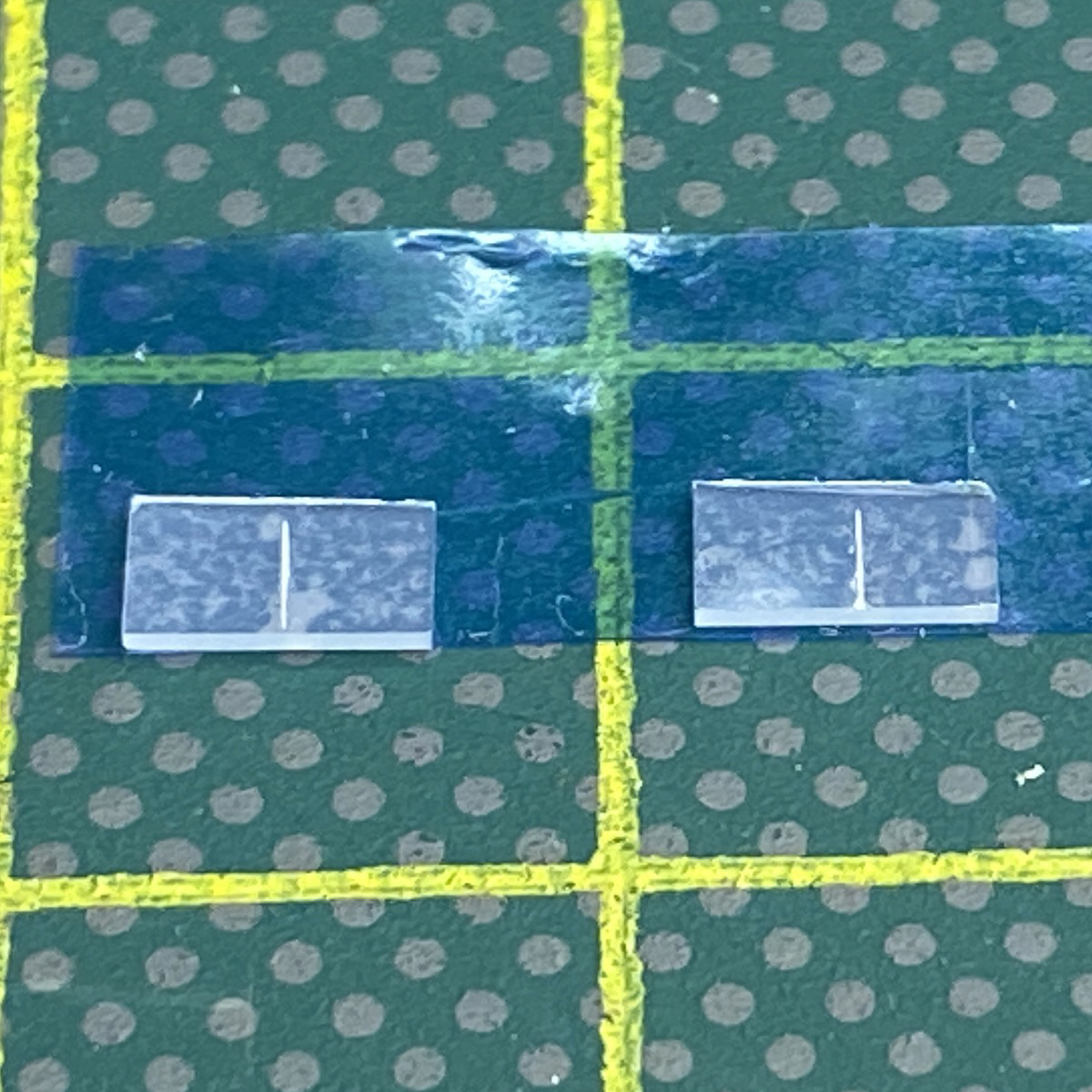

Nanofabricated Photonic Devices

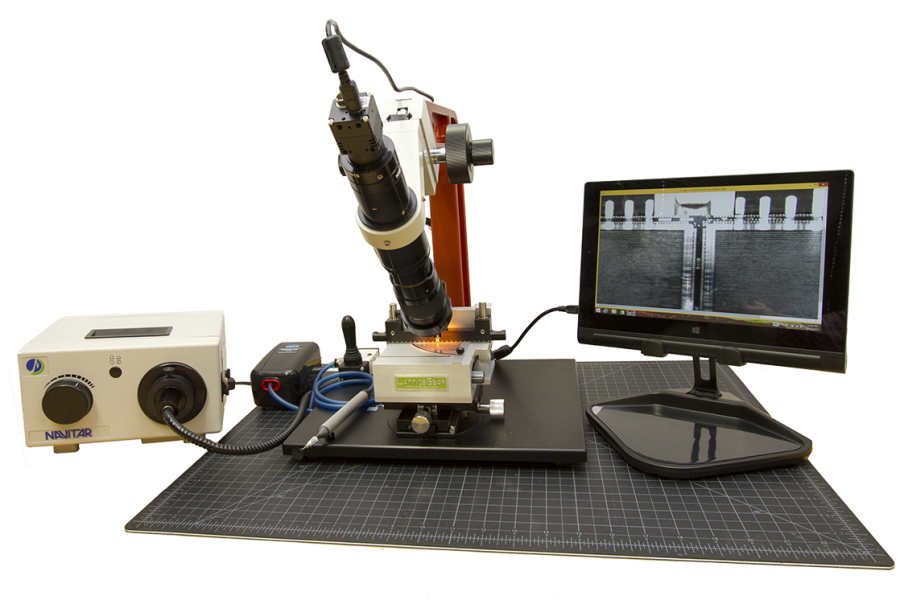

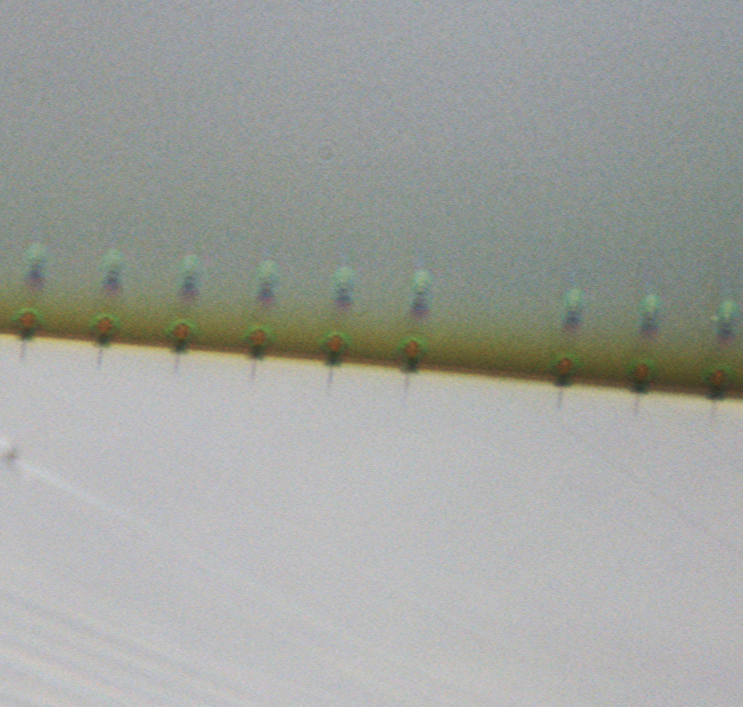

Scientists in the Quantum Photonics Group at the Niels Bohr Institute of the University of Copenhagen are developing new technologies for photonic and quantum-information applications. They are using the LatticeAx to alleviate one of their biggest sample preparation challenges: precise cleaves on small samples without damaging delicate fabricated nanostructures.

Cleaving Strontium Titanate (STO)

STO has a cubic crystal structure with a crystal lattice closely matching Perovskite. It is commonly used as a substrate for epitaxially grown films. Although it is cubic it is surprisingly difficult to cleave. We found that using the FlexScribe with a scribing wheel embedded with diamond we could cleave a 5mm2 and 0.5 mm thick STO substrate (100) in to 2.5x2.5 mm samples. The FlexScribe was used to scribe the samples and small samples pliers used for cleaving.

Cleaving SmB6 at the Cavendish Lab

The LatticeAx was the only way researchers could repeatedly and reliably create damage-free crystal facets, without material loss or waste, required for their studies.

Solutions

Here are some things to consider when cleaving new materials and structures.

- What is my substrate size and thickness?

- What is the crystal structure and hardness of my materials?

- Do I need mirror finish edges (typically needed for photonics devices)?

- Do I want to cleave samples for cross section analysis by SEM?

The solution may require one or more tools to get the job done. For instance:

- For downsizing large wafers into 1 cm2 die, use the FlexScribe.

- For preparing samples that must have mirror finish facets for photonics or SEM analysis. Downsize with the FlexScribe or FlipScribe and make the final cleave with the LatticeAx.

- Preparing samples that have sensitive thin films on the surface. Use the FlipScribe backside scriber to downsize the samples. Make the final cleave using the LatticeAx to obtain mirror finish facets.

Products for Cleaving Nanomaterials and Nanofabricated Devices

Based on your application, LatticeGear can recommend the right tool set. Please CONTACT US!

Cleaving Tools

There are a number of accessories that will be important for your laboratory.

CleanBreak Pliers with 3 Sets of Jaws. After scribing you will need to cleave your sample. It is possible to cleave over a sharp edge but the pliers provide symmetrical force when breaking the glass. Cleanbreak pliers are used for samples 20mm/.75" and larger.

Videos

Watch videos showing the operation of the scribing and cleaving tools and systems.

Publications

Publications (for copies, contact lg@latticegear.com) or for downloadable copies of these publications you must be registered and signed in